[Products]

[Press + Media]

[Basics]

[Technology]

[Application]

[Shop]

[FAQ]

[Contact]

[Links]

[Site Notice]

Acoustic Stealth Technology

As shown in „Basics – Reflections“, we have to avoid as much as possible bad influences caused by reflections and edge refractions.

Best case: such disturbing areas arenīt there. But because some assemblies are neccessary for a functionable driver, we collected a whole bunch of methods and some of them we want to present::

|

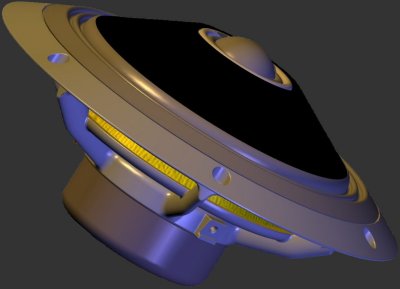

It sounds paradoxical, but in a coaxial system, the woofer ist he greatest enemy of the tweeter. This is because a low-frequency cone has its own requirements on geometry and stability. These usually do not meet the ideals of an infinitely large, plan or spherical surface. Conventional – even highest quality coaxial (and coincident) drivers use a traditional, inward-pointing Cone. That is because it has been always like this and you can use tried and tested technologies, which means you can minimize development effort and costs. Often you can take already existing components, which again means: saving costs. With the driver from Audio Consequence everything is different: A conventional cone is not the best surrounding for a tweeter. First we had to think about everything known and we thought about how to join the requests of the tweeter to his surrounding with the requests of the woofer to stabilization and resonance poverty. In the basic idea the result was so simple but very difficult to translate in practise. Assuming that asphere builds an excellent suitable environment for a tweeter, an inverted cone, which thought peak shows outside, not inside, was the best solution. The tweeter is situated in this thought peak, free off the usual swinging funnel, and there it can make its work mostly undisturbed: the natural reproduction of the frequency area. The points that initiate the power of the voice coil in the dome/cone of the tweeter and the woofer are nevertheless in one level – for perfect coherence of the sound creating places. |

|

In contrast to the flat " cone" – also a possibility to give the tweeter a fitting surrounding – with this solution the benefits for the tweeter will not buy at a disadvantage for the woofer. Stability and poverty response are as safe with a traditional cone – a reason why this has proven itself over decades.

Keeping proved ideas if it makes sense and inveting new technologies if necessary was the base of the construction.

Because many relationships had to be inverted with this new construction, we had to create each component of the driver to its task, which means not only a lot of work, but also the additional advantage to re-think all long-standing and to optimize it.

|

An insignificant component in the first view, that carries a not insignificant influence on the behaviour of the tweeter: The tweeter flange is the front cover of the tweeter, and it docks it with its direct neighbours, the woofer cone. Many models were created, hundreds of measurements were made until we had the optimal shape identities in the end. A short horn intent was kept off: This narrows the angle of the tweeter and makes him so sensitive to his surroundings, but it is precisely this restriction that prevents a balanced development of the high acoustic sounds in the room. No alternative for a uncompromising driver. At the same time usually used diffusers or lenses were eliminated by tests and measures, because they can improve the radiation at a certain angle, but this means also disadvantages at other angles. |

|

|

A surrounds first task is to center the woofer cone and to separate the front and the rear side of the drivers airtight. Belonging to the interpretation of the system it also has to damp the membrane resonance, and care for planned displacement of the cone without changing its spring action. It also has to be long-living in stability, which means a foam surround is no alternative. A multiwave-rubber surround can attend these requirements without any problems, but in case of a coax-construction it also has to take another task, to which it is predestined, because it has another characteristic: It is very flat in relation to it's possible stroke. Even in multiway-systems with tweeter and woofer close together, you can see that the surround forms a barrier in the directly neighbourhood of the tweeter and that results in clear response interferences. Thatīs why it is very important in a coaxial system, where it is situated all round the tweeter. |

|

|

The design of the edges of the basket Usually woofer-drivers have a more or less thick and flat basket-edge. Even if it is good enough for pure low-to mid, it causes problems in a coaxial-system, which we can reduce by beveled design. Cone angle, bead and edge of the basket are forming a homogeneous line for a minimal influence on the tweeter. The fact that the mounting screw holes of the filligree, but still very rigid and resonance-free aluminium die-cast basket are sunk acoustically invisible (stealth ), is a matter of course. Another advantage for DIY: You donīt have to care about the extensive shaping of the basket in the baffle. |

|

|

Also behind the cone, there is something going on: Basically, here is generated the same sound pressure as on the cone front. This sound is normally largely absorbed by damping material in the speaker housing. But what about the early reflections, those who donīt reach the damping material? The sound can be reflected by the motor and the braces of the basket and rejected to the cone. Because normally it is no good acoustic isolator, these reflections add up –with time delay - to the sound emitted just from the cone -- distortions and interferences are the result. The braces of the basket of the Audio Consequence coaxial driver are elliptical in shape and offer only a minimal attack surface for maximum stability in the level of vibration. Although other manufacturers have recognized the problem, however, if at all, they mostly round off only the clearly visible back side of the braces, while the much more important front side remains flat. Also the inner flange for the motor has been carefully rounded at the top for the same reasons. The support surface of the spider can not be accousticly defused by rounding. Therefore it is made as thin as possible and at least its backside is rounded to minimize the sound refraction at the edges. |

|

|

When we look at the rear sound reflections, a conventionally constructed motor with a ferrite magnet is a disaster. For long time, we only had few alternatives and thatīs why these reflective " monsters" were successful. With the currently available advanced magnetic materials, it is now possible to construct motors so slim that they find their place in the woofers voice coil and donīt offer a significant reflection surface, if there is no dustcap Wich other advantages you can reach with a cleverly studied and constructed Neodymium motor, we tell you in the chapter “Technology – Motors”

|

|

Copyright(c) 2018 Audio Consequence. Alle Rechte vorbehalten.